Save and Reliable Material Handling of Steel Flat and Round Stock

PML Series Neodymium/Rare Earth Lifting Magnets

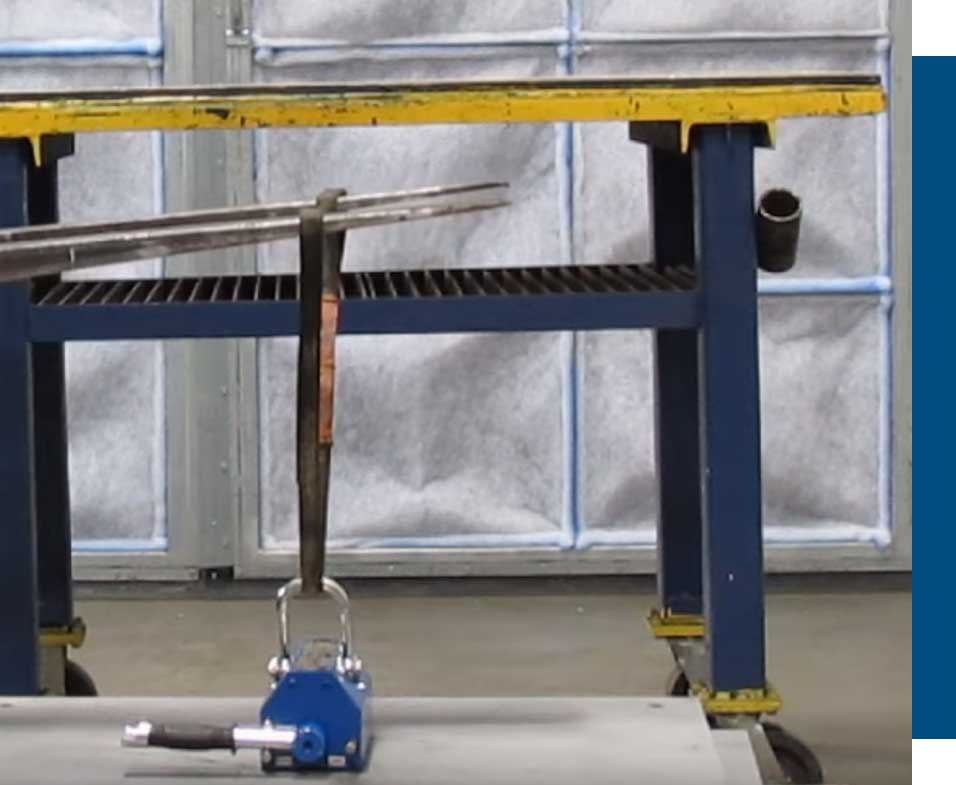

The Permanent Magnetic Lifter (PML) – a below-the-hook permanent magnetic lifting machine allows steel handlers to quickly and simply maneuver steel plate, pipes and rods without the use of slings, chains and blocking. In most applications, a two-man job could be accomplished with one man utilizing the lifting magnet. Being a permanent magnet, no external power is required, therefore eliminating the hazards associated with power magnets.

| Part No. | Load Limit (flat) | Load Limit (Round) | Unit Weight |

|---|---|---|---|

| PML1 | 220lbs / 100kg | 66lbs / 30kg | 7lbs / 3kg |

| PML3 | 660lbs / 300kg | 297lbs / 100kg | 22lbs / 10kg |

| PML5 | 1320lbs / 500kg | 594lbs / 150kg | 51lbs / 12.5kg |

| PML10 | 2200lbs / 1000kg | 661lbs / 300kg | 117lbs / 53kg |

Permanent Magnetic Lifter Features

Permanent Magnetic Lifters are used across several industries to hoist and move heavy metal objects. These units do not require the use of electricity and are much safer to operate since there is no concern for product failure due to power surges or outages. In addition to improved safety and performance, Magnetic Lifters powered with rare earth materials are a convenient way to tackle moving heavy loads with a single operator. These lifters are especially useful in production and fabrication facilities to load and remove plate and round stock into lathes, milling machines, plasma and water jet tables.

- Clamp, Maneuver and Release Round, Flat and Angled Steel Efficiently

- Easy to Use, One Man Operation

- Reduced Product Damage Caused by Traditional Material Handling

- Eliminate Blocking, Chains and Straps (Slings)

- Self Contained Compact Design Allows for Workstation Mobility

- Rare Earth Permanent Magnets Do Not Require Any Additional Power Supply

- Eliminate Hazard Associated With Electromagnetic Lifters

- 3:1 Safety Factor Contributes to the Exceptionally Safe and Reliable Operation

- Self Locking Lever Prevents Accidental Deactivation

- Suspended Below the Hook or Utilized with Spreader Beam

Permanent Magnetic Lifters can be found in many industries:

- Construction

- Steel fabrication

- Machine shops

- Factories

- Warehouses

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

Industrial Magnetic Sweepers are designed and built for industrial applications that require…

The iMAG-RK is a Permanent Magnetic Rake developed for processing facilities that operate metal detectors.

Vibratory Magnetic Separators are the evolution of tramp metal separation for vibratory conveyors…

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.