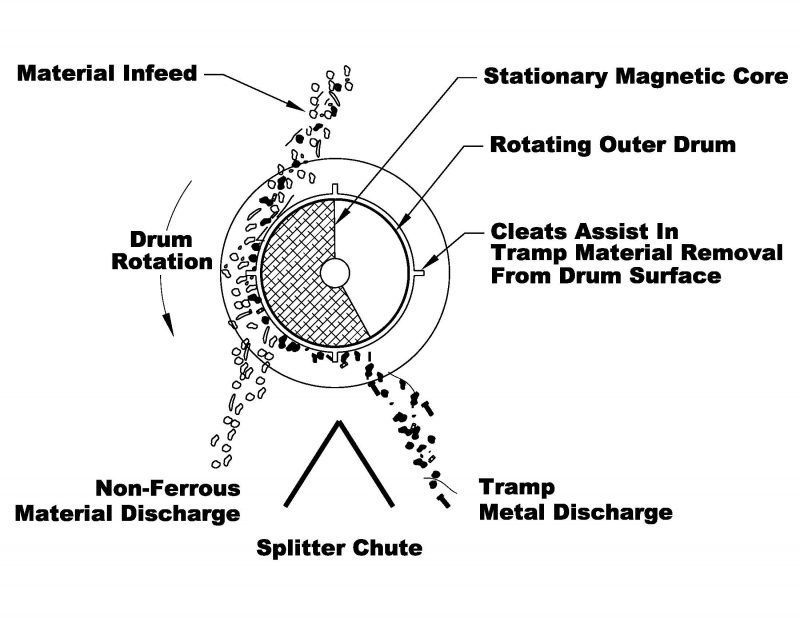

Magnetic Drum separators utilize a stationary magnetic core within a rotating outer shell.

Magnetic Drum Separator Applications

Magnetic Drum Separators are used to separate metal particles from slurries, granules or powders. These industrial magnets work on a high-volume basis for applications where there is a great deal of continuous turnover of product. These continuous self-cleaning drum magnets are ideal for applications where there is a high level of ferrous and para-magnetic contamination.

As material is introduced to the drum surface, a magnetic field attracts ferrous material to the rotating outer drum. This action continually conveys the captured ferrous material out of the product flow to the ferrous discharge area creating a self-cleaning action.

Common uses for magnetic drum separators include magnetite recovery in heavy media mining circuits, tramp metal extraction, and product purification.

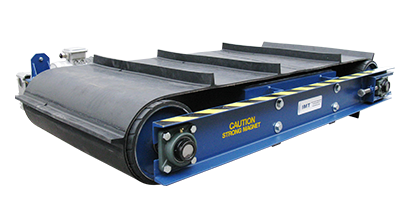

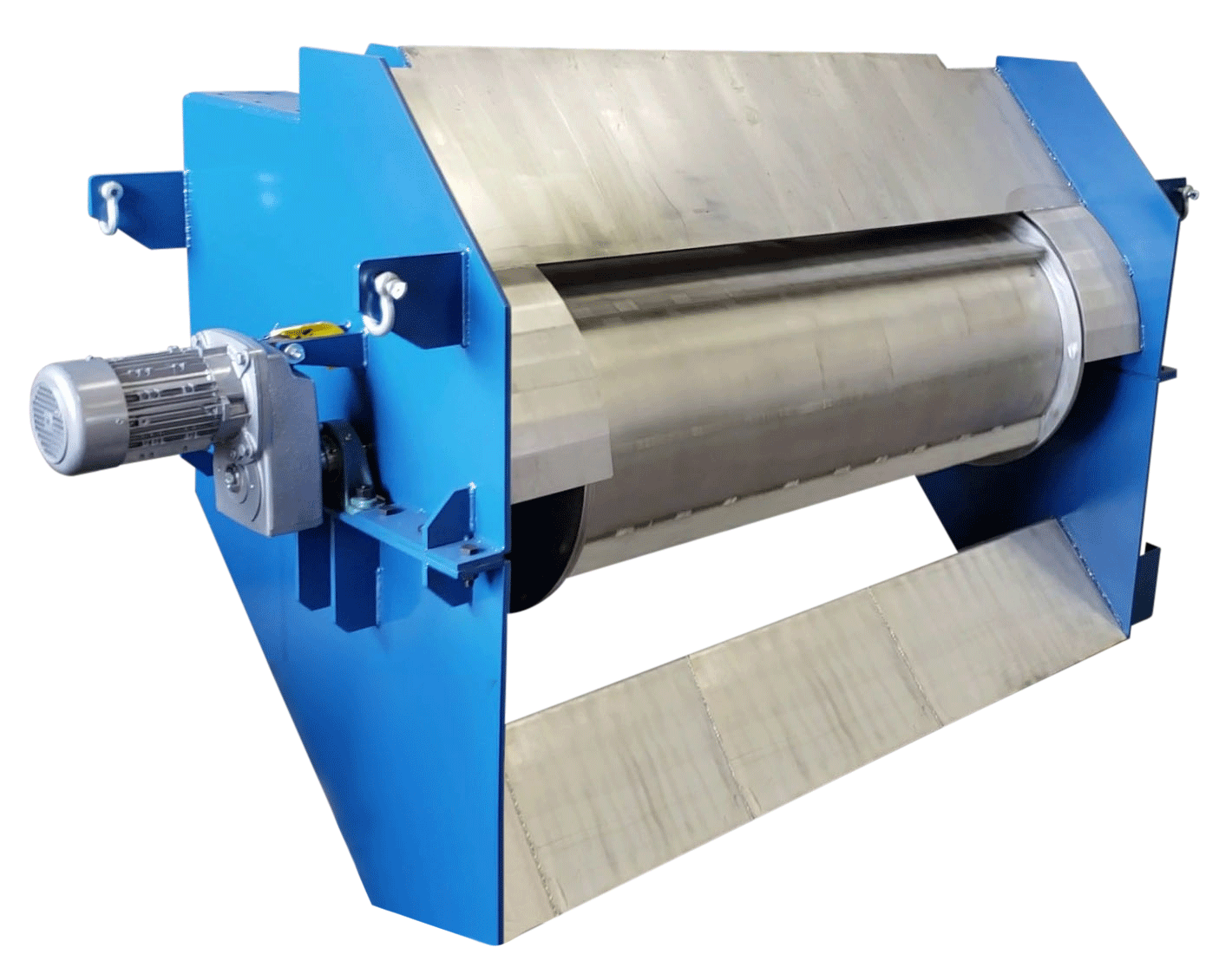

Magnetic Drum Separators

IMT Magnetic Drums are designed and built to your specific application requirements providing maximum efficiency and consistent product flow within an optimal footprint.

- Available in rare earth, ceramic (ferrite) and electromagnetic

- Wet and Dry options

- Optional IMT Infeed Conveyors ensure a consistent metered feed over the drum surface

- Adjustable Splitter Chutes provide an effective separation cut between ferrous and non-ferrous material

At Innovative Magnetic Technologies, our experienced team will manufacture on our site to meet your exact needs. Our application specialists have the skills and know-how to provide you with a unique product that will improve your productivity and quality for many years to come.

How Drum Separators Work

As the material is introduced to the drum surface, the magnetic field attracts ferrous material to the rotating outer drum. This action continually conveys the captured ferrous material out of the product flow to the ferrous discharge area creating a self-cleaning action.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.