Permanent Magnetic Separation

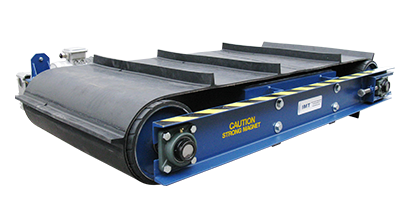

IMT G5 Series Suspended Plate Magnets

Innovative Magnetic Technologies’ G5 Suspended Plate Magnets to provide industry with economical and dependable magnetic protection for process equipment. The permanent magnetic forces provide continuous and effective removal of unwanted tramp metal. The suspended plate magnet will increase uptime, reduce maintenance costs and provide a metal free product.

The G5 Upgradeable Advantage

Every plant is unique. IMT’s G5 Suspended Plate Magnets are custom designed in differing sizes and strengths to ensure proper fitment and maximize effectiveness for specific applications. Our internal core design maximizes magnetic field strength ensuring maximum reach out and holding forces.

The G5 Core Design

The G5 Cross Belt Upgrade Option

The G5 Cross Belt Upgrade Kit fully automates the separation and discharge of ferrous tramp material. The G5 CBU Kit is easily installed with only four (4) bolts and splicing the cross belt system. This kit is only available for IMT G5 Series suspended permanent magnets.

With this self-cleaning cross belt system upgrade, the IMT’s G5 suspended plate magnet will increase uptime and reduce maintenance costs while providing a metal free product.

The G5 Actuated Maintenance System (AMS) Option

Watch YouTube Video – IMT AMS Demonstration

The system is simple to install, offers full height adjustment and includes a mounted winch, enclosed AGM battery, waterproof fully interactive on-board charger, lifting clevises and a remote switch which can be used from either side of the conveyor. The stand is pre-wired and only requires a 120v connection for charger, or an operator can opt for the solar power option to maintain the battery charge. Optional discharge capture tray available.

Innovative Magnetic Technologies’ G5 Suspended Plate Magnets provide industry with an economical, dependable, and flexible magnetic protection for industrial process equipment.

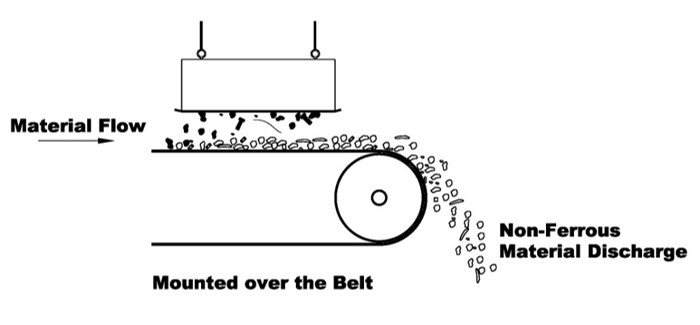

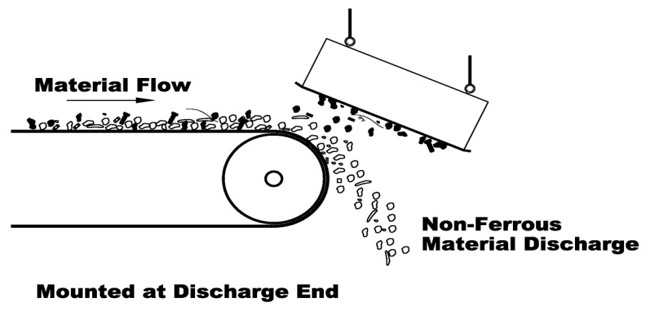

Installation Configurations

Suspended Plate Magnets are useful across many industries for extracting ferrous contaminants from production lines. Suspended plate magnets offer exceptional efficiency since they require no energy consumption and as such, will not fail in the case of power fluctuations or shut off. IMT’s powerful magnets are typically installed either directly above a conveyor belt line or suspended over the conveyor head pulley at the discharge point.

Discharge Point Advantage

- The advantage of installing a suspended permanent magnet over the discharge point is that the all conveyed material changes from a static to a kinetic state, liberating the ferrous tramp material from the conveyed product thereby improving separation efficiency.

Direct Overhead Advantage

- Advantage of installing a suspended permanent magnet over a conveyor belt is ease of accessibility, less structural requirements, and straight forward installation.

Quality at the Core

Quality control plays a critical role in all aspects and is a system set in place to help maintain standards in IMT’s manufacturing process.

Custom design, fabrication and assembly involves multiple processes; it is critical to have well-documented quality control procedures. IMT operates an in-house quality assurance program following materials and components from receipt of delivery through fabrication to final product ensuring the highest quality standards are met.

Related Products

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.

Contact Innovative Magnetic Technologies Today!

Connect with experienced and knowledgeable industrial magnetic application specialists. We are ready to answer your industrial magnetic equipment questions.